Our Equipment

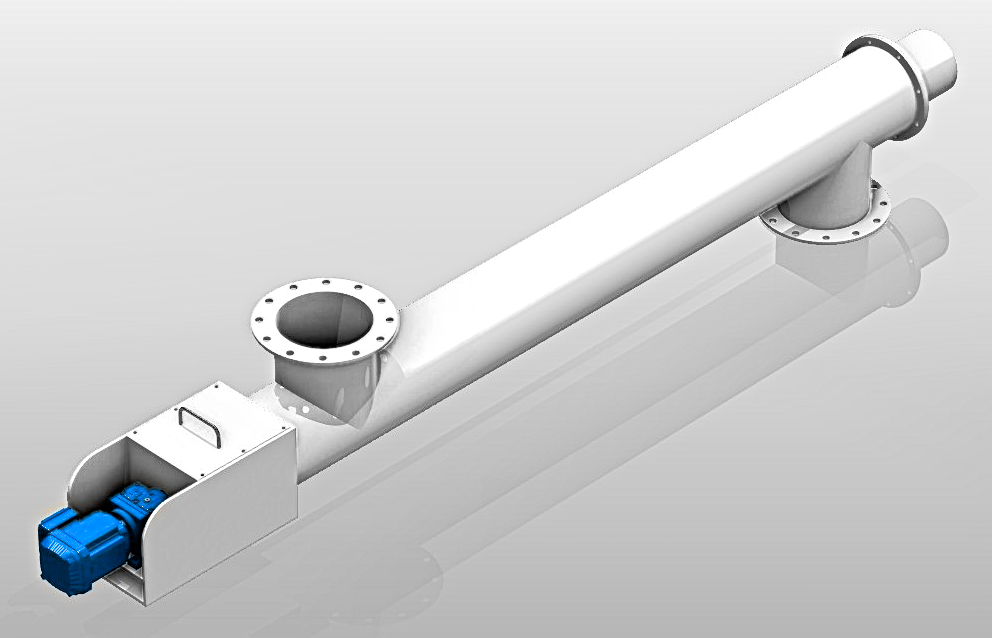

SCREW CONVEYORS

Screw conveyors are typically used for the bulk handling of free-flowing products such as grain, cereals, feed, wood chips, powders, sand, and cement. We provide screw conveyors made from mild steel or stainless steel in various sizes, lengths, and configurations. The two most common types are tube and trough conveyors.

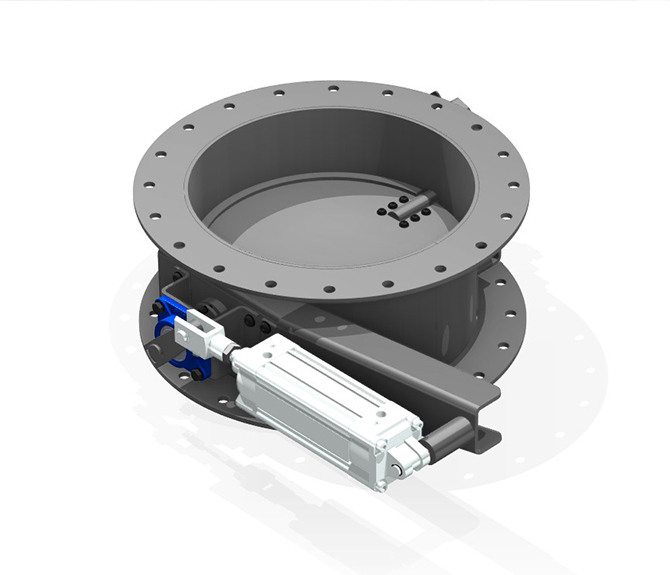

BUTTERFLY DAMPERS

Butterfly dampers are used in low-pressure flow control environments, suitable for isolation and flow regulation. Our butterfly dampers are robust, made from laser-cut plates.

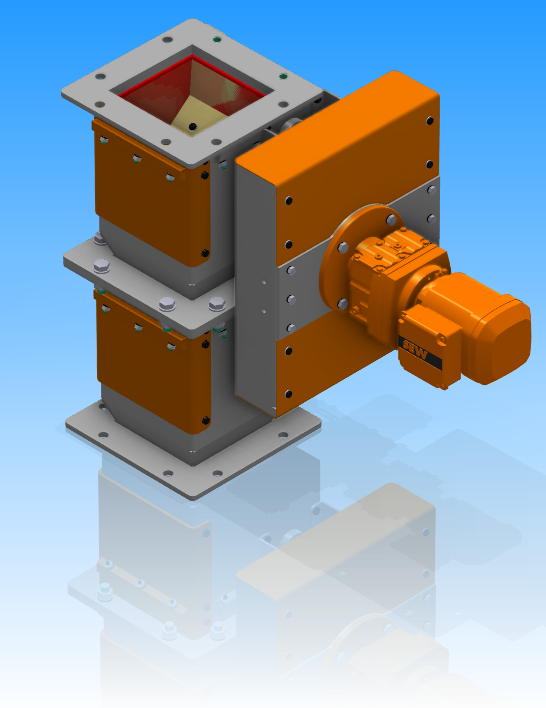

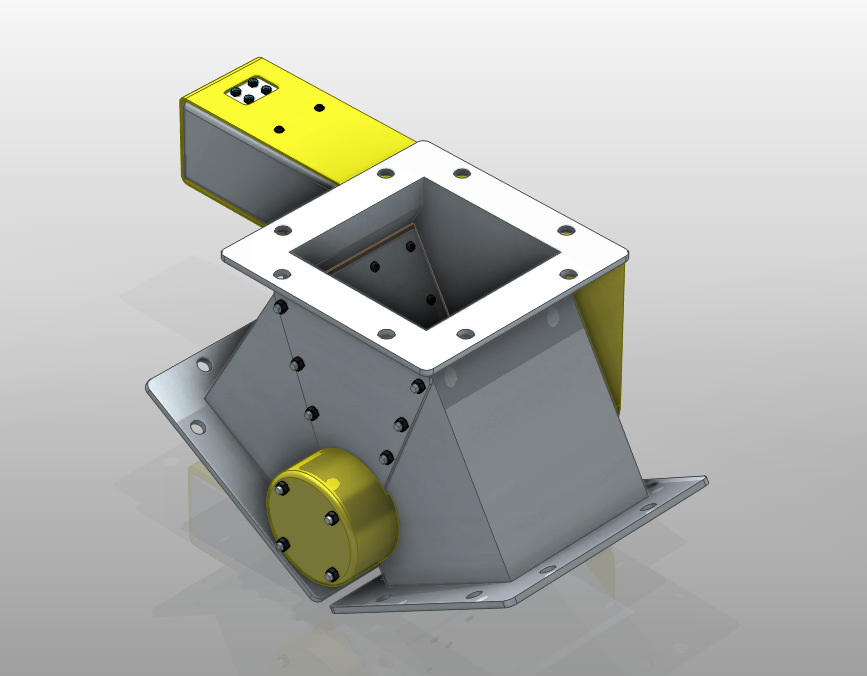

DOUBLE FLAP VALVES

Double flap valves are primarily used instead of rotary valves where abrasive materials may jam, damage, or wear out the rotary valve. Mech-Tem double flap valves excel in preventing spillage during operation.

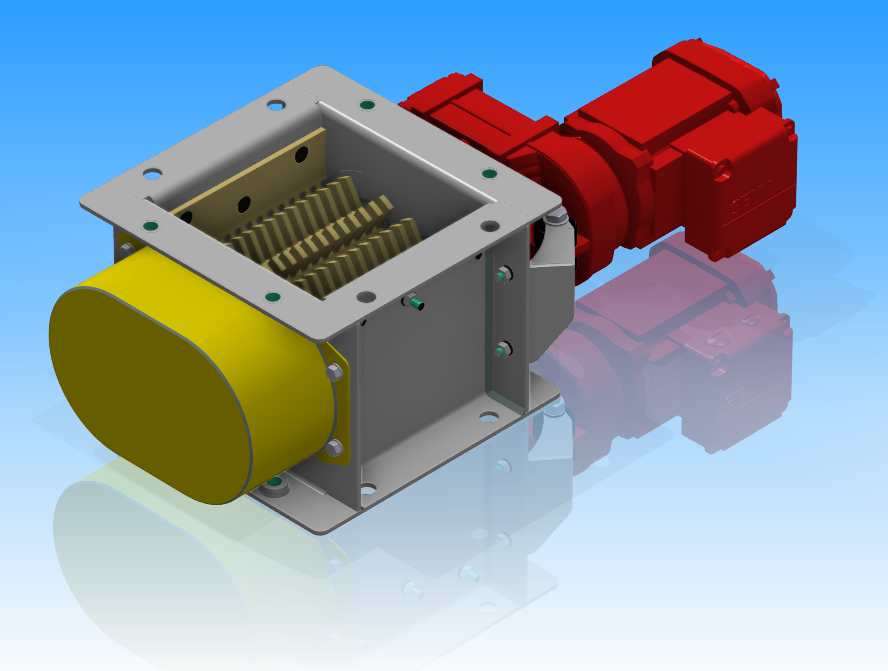

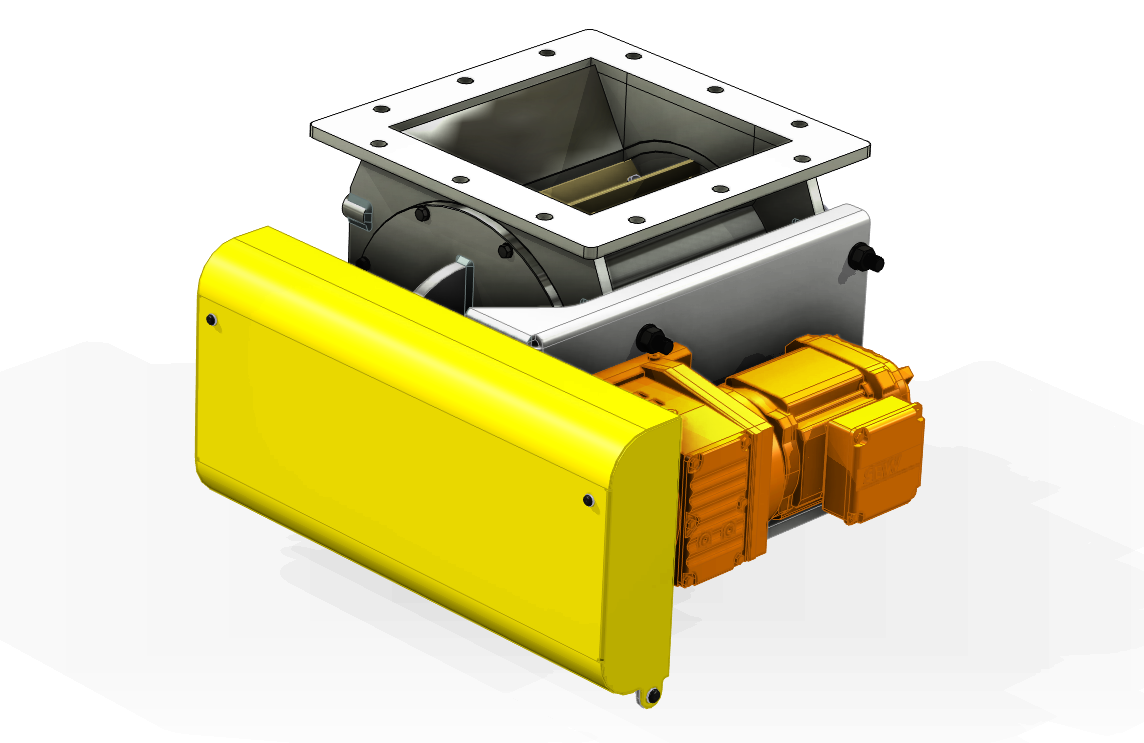

LUMP BREAKERS

Lump breakers are designed to reduce softer and abrasive products such as filter cakes, foodstuffs, fertilizers, and fly ash into smaller sizes for further processing. Our units can be integrated with our rotary valves, screw conveyors, or other equipment.

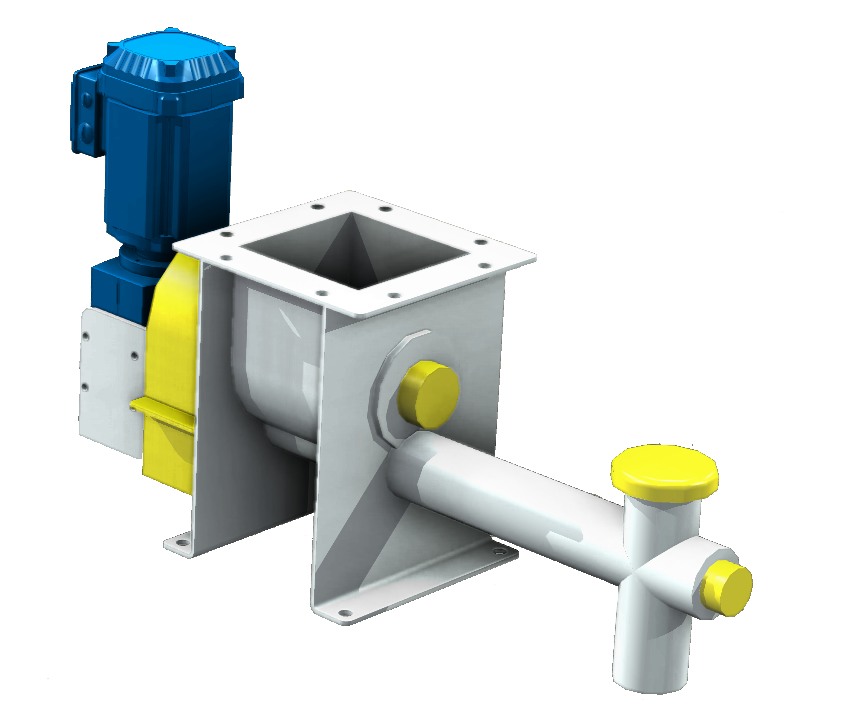

DOSING SCREWS

Dosing screws are critical for accurate measurements, especially in the food and pharmaceutical industries. Mech-Tem dosing screws have tight tolerances to ensure precise dosing, and the motor can include a variable speed controller for enhanced accuracy.

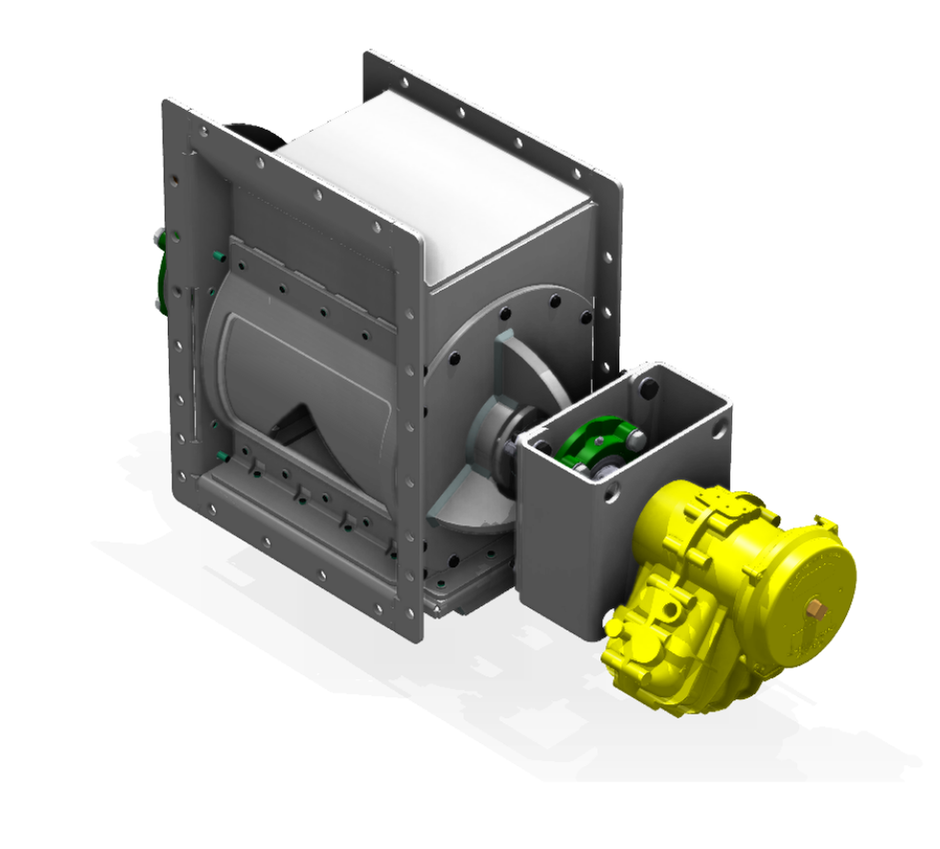

ROTARY FEEDERS

Rotary feeders are ideal for limited space, providing controlled feeding of bulk material from silos and hoppers. Our rotary feeders feature a rigid casing machined to tight tolerances to minimize leakage.

FLOW CONTROL GATES

Flow control gates allow for controlled discharging of bulk solids from silos and bins and can be installed on air slide conveyors for shut-off, flow regulation, and metering. Constructed from laser-cut plates, Mech-Tem flow control gates ensure both rigidity and precision.

FLAP DIVERTERS

Flap diverters divert the gravity flow of bulk solids from one feeding point to multiple receiving points. Bulk material in powdered, pellet, flake, or granular form flows freely through the diverter valve, which is typically installed on outlets of dry bulk storage silos, bins, chutes, and conveyors.

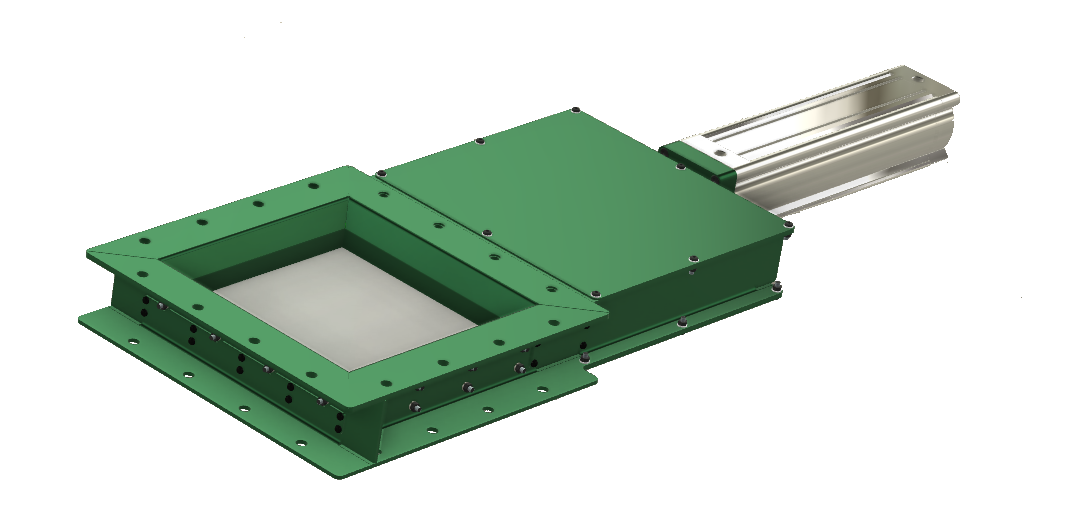

SLIDE GATES

Mech-Tem slide gates are constructed using rigid steel plates, all laser-cut to meet tight tolerances. The gate blades are made of 304 stainless steel to provide a smooth, corrosion-resistant surface. Replaceable bearings are utilized instead of pins to reduce friction, particularly helpful for hand-operated slide gates.

PNEUMATIC CONVEYING

We specialize in various types of pneumatic conveying systems, including:

– Lean phase pneumatic conveying

– Dilute phase pneumatic conveying

– Dense phase pneumatic conveying

– Air slide conveyers

Our services include repairs and refurbishments for all types of pneumatic conveying systems, including their equipment and accessories. Additionally, we design and manufacture pneumatic conveying systems as replacements for mechanical systems or as add-ons in existing plants.

A pneumatic conveying system utilizes gas flow as the medium to transfer bulk materials of nearly any type from one or more sources to one or more destinations. Air is the most commonly used gas; however, in cases involving reactive materials or where there is a risk of dust explosions, alternative gases like nitrogen may be used.

Well-designed pneumatic conveying systems can be more practical and economical compared to alternative mechanical systems (such as belt conveyors or screw conveyors). These systems are relatively cost-effective to install and operate.

Pneumatic systems are fully enclosed, and, if required, can operate without moving parts coming into contact with the conveyed material. Their enclosed nature makes them cleaner, more environmentally friendly, and easier to maintain. They also offer flexibility in terms of rerouting and expansion; a pneumatic system can transport a product wherever a pipeline can be installed.

Here are the types of pneumatic conveying systems we service, design, and build:

1. **Lean Phase Pneumatic Conveying**: This system uses a high volume of air at low pressure to move products. A blower is typically used to create sufficient pressure to transport the material, usually with an air-to-product ratio of less than 1:1. Lean phase conveying operates at air velocities above 20 m/s. The combination of high velocity and low pressure allows the air to do more than just convey the product. In this system, the material is kept in the center of the pipe in a suspension flow. The lower pressures also reduce the risk of damage to the material if there is a sudden drop in pressure in any section of the line.

2. **Dilute Phase Pneumatic Conveying**: This system often uses a positive displacement (PD) blower to move less air at higher pressure than lean phase conveying. The increased pressure allows it to transport some materials with an air-to-product ratio of up to 7:1, typically operating at pressures below 100 kPa and velocities of 18 m/s or more. Like lean phase, dilute phase conveying also uses suspension flow.

3. **Dense Phase Pneumatic Conveying**: This system uses compressed air to push dense slugs of product through the line. It generally operates at pressures no more than 400 kPa (though higher pressures may be possible) and with air velocities typically less than 10 m/s. Because compressed air pushes the material instead of suspending it, products remain intact during transport. The product-to-air ratio in dense phase systems is very high, typically maintained above 20:1 and can be as high as 100:1 depending on the material. However, materials with particles larger than 10 mm in diameter generally do not work well in dense phase systems, as the air tends to flow around rather than push them. In contrast, lean and dilute phase systems can accommodate nearly any particle size and shape.

For these pneumatic systems, we can supply long-radius bend elbows (with and without wear coats), pneumatic drum diverters, drop boxes, and more.

**Air Slide Conveyors**: These systems utilize the force of gravity to facilitate movement without any moving parts. Material is fluidized through a porous medium using low-pressure air. Flow is achieved by sloping the air slide conveyor to match the fluidized angle of repose of the powdered material. At the correct slope, fluidized materials flow with the consistency of a liquid. For air slides, we offer accessories and equipment such as modified slide gates (horizontally and vertically), flow control gates, drum diverters, and more.

The vent pipe outlet is normally plugged. The vent pipe is mounted in conjunction

with the dust extracter.

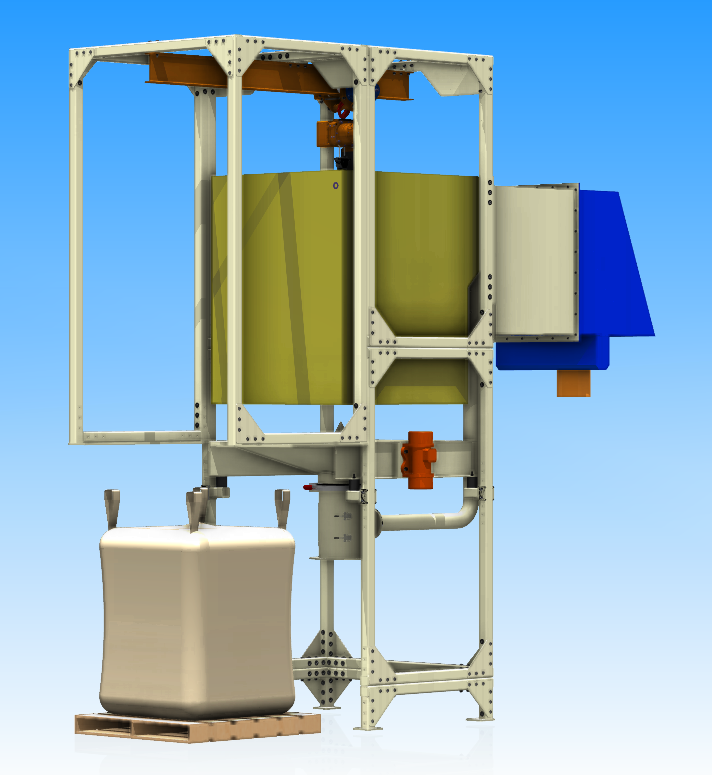

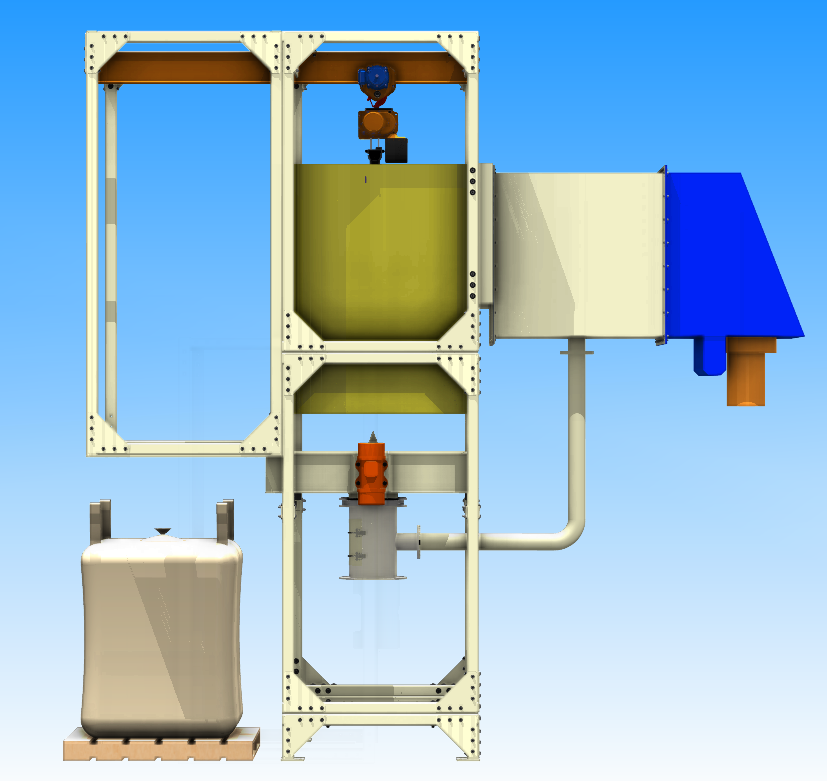

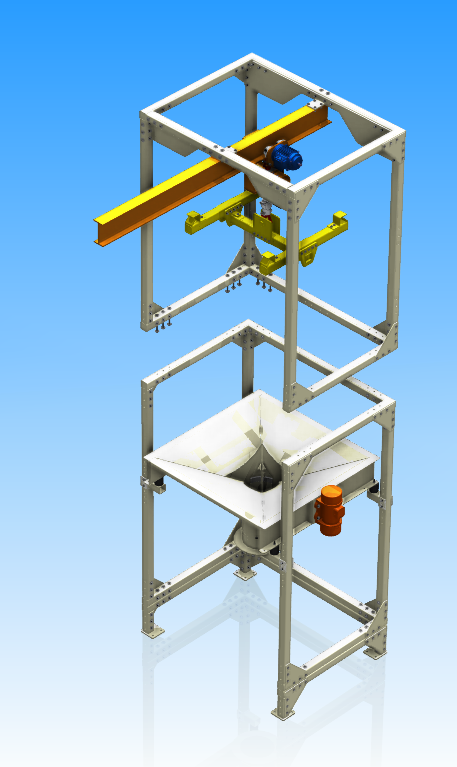

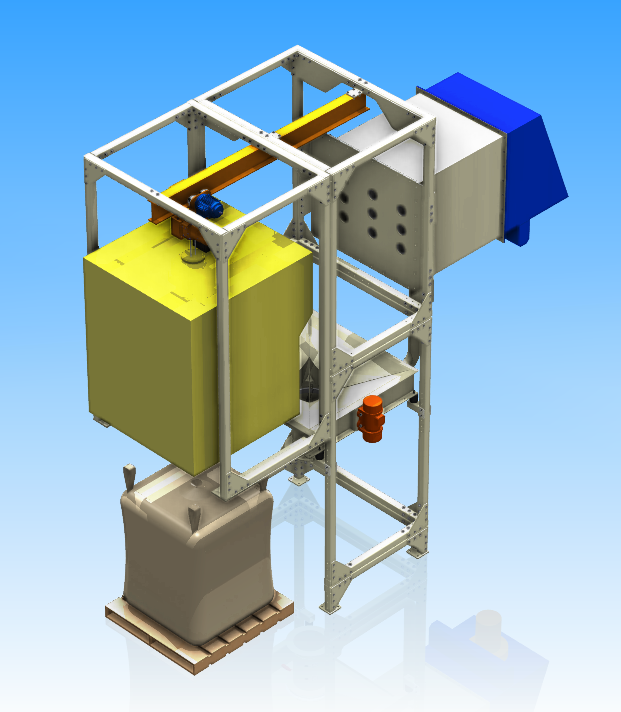

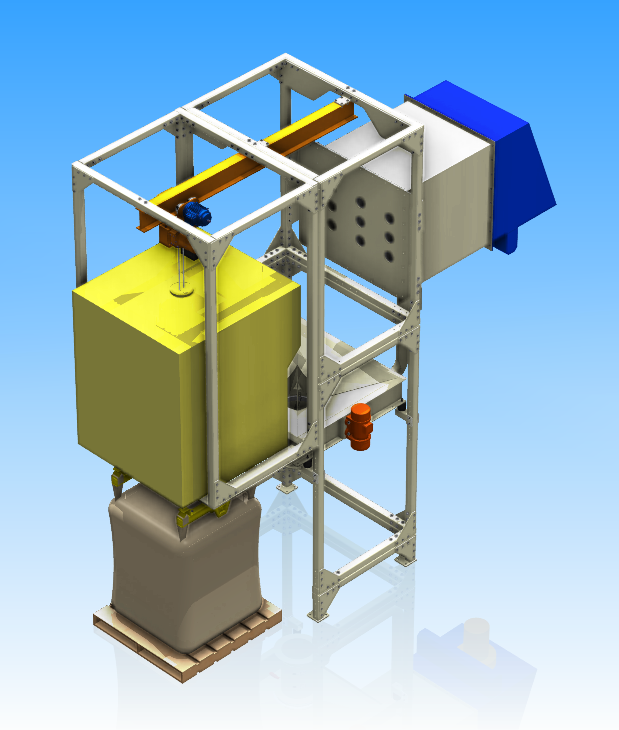

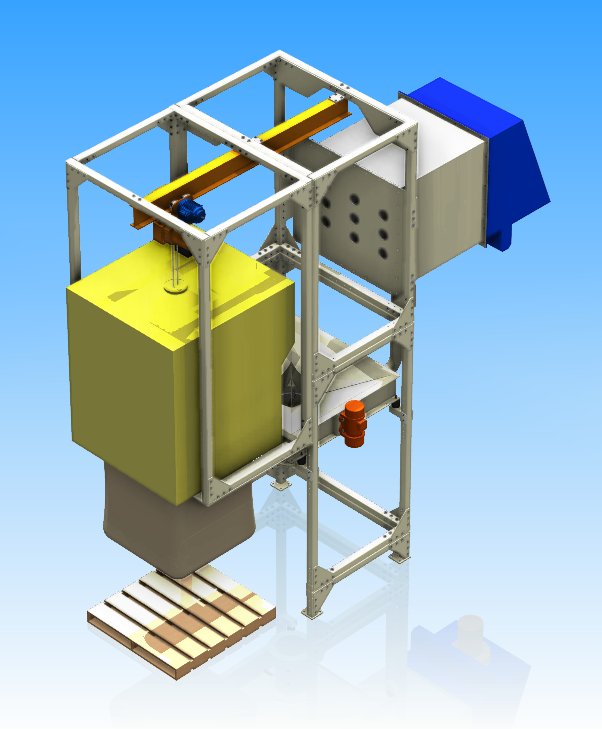

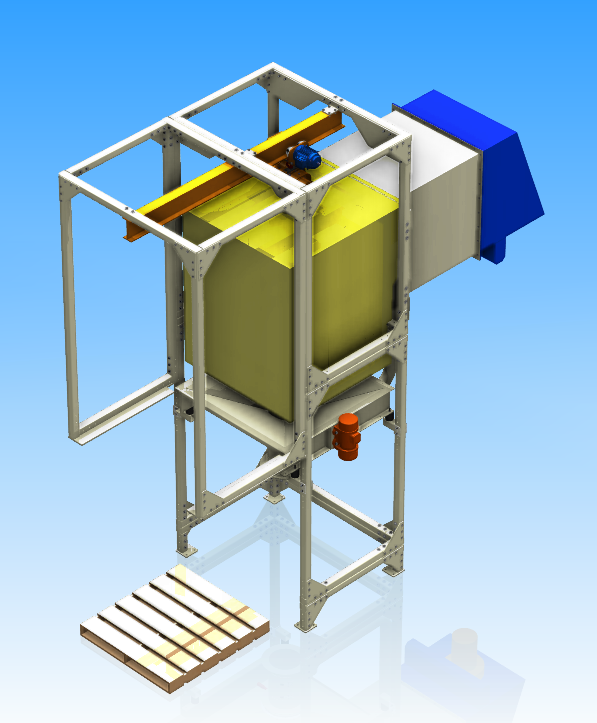

BULK BAG UNLOADER

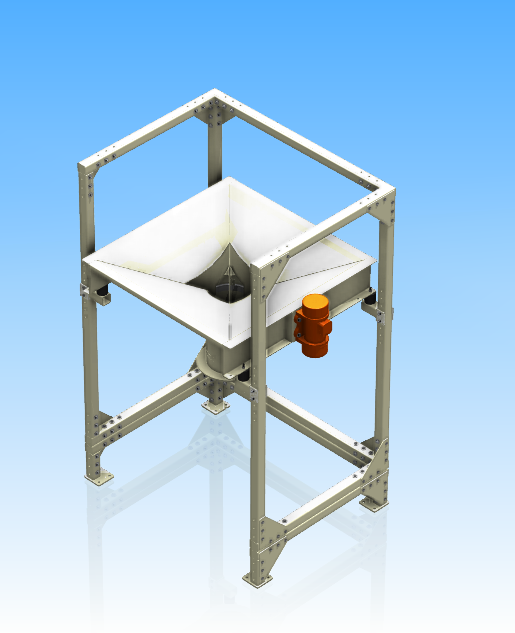

Unloading bulk bags can be challenging and time-consuming, especially with bags that hold up to 1 m³ or more, and weights reaching up to 2 tons can make the process labor-intensive. Our custom-designed Bulk Bag Unloader addresses these challenges, enhancing efficiency and minimizing the risks associated with bag unloading. Standard units accommodate 1 m³ bulk bags weighing up to 2 tons. Our Bulk Bag Unloaders are robust, modular in design, and can be easily upgraded.

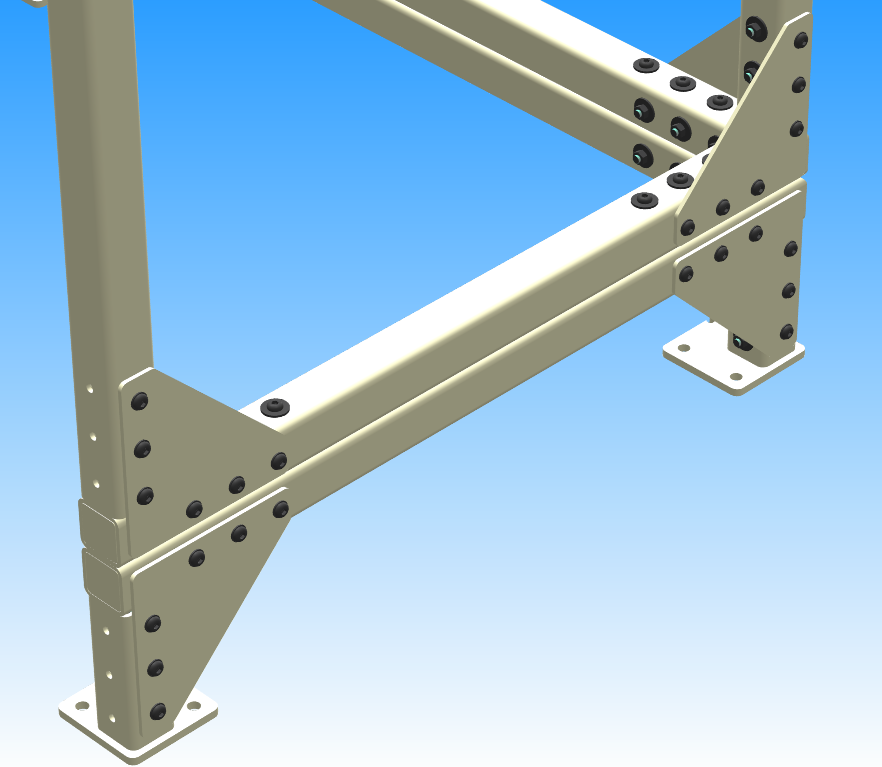

The frames of the units are bolted rather than welded to allow for easy assembly, disassembly, and transportation. Heavy-duty 75mm square tubing is used to create a safe and sturdy structure, which can be made from carbon steel or stainless steel.

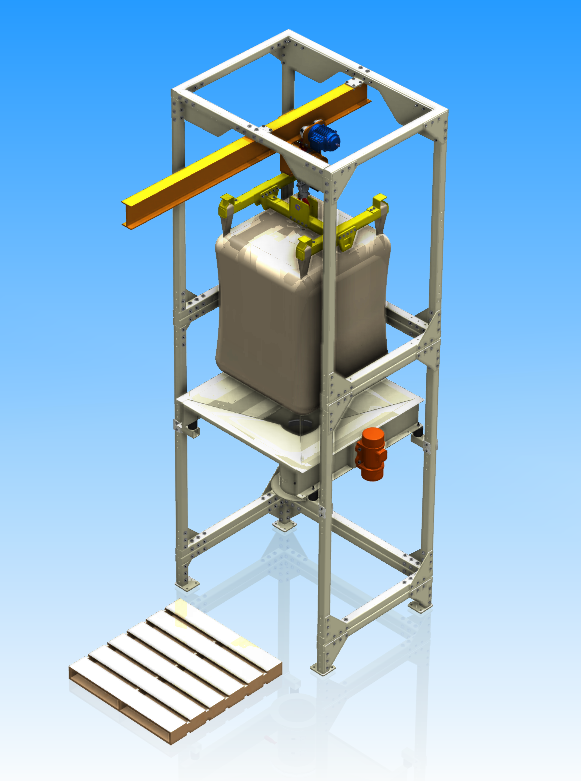

The top frame, which includes the hoist, can be added during initial assembly or fitted later when semi-automatic unloading is required.

For dust-free, automatic unloading, a dust extraction filter unit can be incorporated alongside a loading frame, bag housing, and vent pipe.

The spreader bar moves down onto the top of the bag, where it will be manually connected by an operator. The bag housing rests on the loading frame. The spreader bar pulls the bag into the bag housing, making it ready to move back over the tray.

The spreader bar moves down unto the top of the bag. It will be manually connected by an operator. The bag housing is resting on the loading frame.

The spreader bar pulls the bag into the bag housing.

The bag housing with the bag is ready to move back over the tray.

Once over the tray, the bag housing lowers onto the tray, sealing the bag on top of it and connecting to the dust extractor at the back. The bag is opened using a bag cutter.

FUME CABINET

A fume cabinet (also known as a fume hood or laboratory fume hood) is a ventilated enclosure used in laboratories to safely contain and remove hazardous fumes, vapors, dust, and airborne contaminants produced during experiments or chemical handling. Its primary purpose is to protect laboratory personnel from inhaling toxic or dangerous substances.

Key features of a fume cabinet include:

**Ventilation:** Equipped with a powerful exhaust system that draws in air, removing harmful fumes through ducts to an external area.

**Sash:** A movable window or door at the front allows access while acting as a barrier between the user and harmful chemicals.

**Work Surface:** A flat surface inside the cabinet where experiments are conducted.

**Filters:** Some fume cabinets use filters (e.g., HEPA or carbon filters) to scrub the air before it is recirculated or vented.

Fume cabinets are commonly used in chemistry labs, pharmaceutical research, and any setting where hazardous chemicals are handled. They are essential for maintaining a safe working environment.